MANUFACTURERS' REPRESENTATIVES

e-MOBILITY

e-Mobility Principals

e-Mobility Principals

Established in 1970, KRAH Group, with headquarters in Germany, is the global market leader of automotive resistors which they manufacture in plants in Europe, Asia, and South America. Their products include suppression resistors for ignition coils, and pre-charge resistors for EV applications. They are TS 16949 certified.

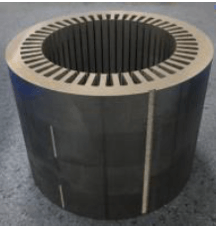

Established in 1974, POSCO SPS manufactures steel lamination products for the automobile, consumer white goods, and high-speed railroad industries. The company located near Seoul, Korea, produces motor cores including automatic stacking embossed cores, welding cores, emboss-free cores, rotor skew stacking cores, and self-bonding cores. POSCO SPS is IATF 16949 certified, employs 555 people, and manufacturers in facilities located in Cheonan and Pohang, South Korea with additional stamping facilities in India and China.

Thomas Engineering Company, located in Minneapolis, MN, has been a manufacturer of the highest quality precision metal stampings since its founding in 1962. TEC is a leader in the manufacture of precision micro-miniature, miniature and medium size stampings. Value-added Secondary Operations enable finished parts to be integrated immediately into product assembly operations. The facility is equipped to efficiently produce millions of parts per month. TEC also offers complete engineering and design assistance and is ISO 9001: 2000 registered.

Established in 1966 and located in Incheon, Korea. Dongbo manufactures high quality machined engine, transmission chassis components, fuel rail assemblies, piston pins, chain sprockets, balance shaft assemblies and aluminum transmission components throughout their six facilities in South Korea. Dongbo has achieved IATF 16946 quality certification.

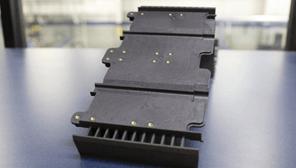

With more than 70 years of experience in Manitowoc, Wisconsin, Kaysun is recognized as a leader in providing highly engineered injection-molded products throughout the world. Kaysun is a preferred partner to automotive leaders who require injection molding expertise for critical-use and tight tolerance applications. Kaysun’s capabilities include two-shot, insert molding and overmolding as well as value-added secondary operations. They are IATF 16949:2016 certified and OEM customers include Ford, GM, Honda, BMW, and Nissan.

With over 35 years of rubber molding experience in the automotive industry, Jefferson Rubber Works, Inc. (JRW) located in Worcester, MA, is the right choice when choosing a rubber molder. By employing modern methods and technology to replace aging compression and transfer molding methods, JRW can reduce costs and produce superior solutions to meet the needs of automotive companies.

JRW is ISO 9001 certified, utilizes EDI for accurate and efficient order processing, and offers both JIT and Kan Ban delivery methods.

Located in Jamestown, New York and established in 1891, Anderson Precision Inc. supplies precision turned metal parts and pneumatic push-in cartridge assemblies to the automotive and other industries. A variety of metals are machined including steel, stainless steel, aluminum, brass, copper, and phosphor bronze. There are 115 employees at the 80,000 square foot, IATF 16949:2016 certified, Jamestown facility.

Follow Us

© 2024

All Rights Reserved | Eynon Associates Inc.